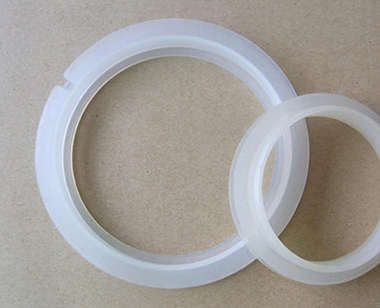

Liquid silica gel products sealing ring equipment requirements, sealing ring is a very important and effective way to solve the leakage problem of hydraulic system. If the sealing ring of the hydraulic system is not good, the silicone seal ring may leak out, and the leaking oil will pollute the environment; It may also make air into the oil suction chamber, affecting the working function of the hydraulic pump and the smoothness of the movement of the hydraulic performance components. Therefore, the reasonable selection and planning of sealing ring equipment is very important in the planning of the hydraulic system. The requirements of liquid silica gel manufacturers for sealing ring equipment are as follows:

1. Sealing ring in the working pressure and certain temperature range, should have a good sealing function, and with the increase of pressure can actively improve the sealing function.

2. The friction between sealing ring equipment and moving parts should be small, and the friction coefficient should be stable.

3. The sealing ring has strong corrosion resistance, is not easy to aging, long working life, good wear resistance, and can be actively compensated to a certain extent after wear.

4. Simple structure, convenient use and maintenance, so that the sealing ring has a longer life.

Device precautions and cleaning device location:

1, remove the burr in the process of sealing device movement;

2. Apply lubricant on the seal;

3, maintain the sealing surface is not damaged;

4, check to confirm that the size of the seal is correct;

5, on the demand for deformation device seals using the corresponding device.