The differences between liquid silica gel and solid silica gel are as follows:

Differences from the field of use:

1, liquid silica gel is generally used in baby products and kitchen supplies and medical supplies in liquid silica gel products, can be directly in contact with food and human body;

2, solid silica gel is generally used in daily necessities and industrial miscellaneous parts and auto parts;

3, the safety of liquid silica gel and solid silica gel: liquid silica gel is high transparent and high safety food grade information, molding does not increase the auxiliary information such as curing agent, sealing feeding molding. Solid silica gel is clear information, molding needs to add curing agent to accelerate the curing time, open mold feeding molding.

From the molding method on the difference:

1, liquid silica gel is injection molding liquid silicone rubber (LSR) : full name is injection molding liquid silicone rubber, curing equipment for injection molding machine. Injection molding machine process is very simple, high accuracy of products, high output (A/B glue mixed at A certain temperature in A few seconds forming), save people, save electricity, save information and other advantages, can produce all high temperature glue produced products; It is a mainstream of silicone rubber data development in the next year;

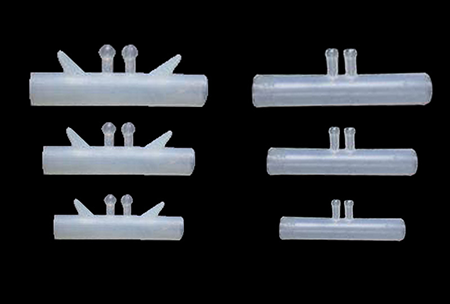

2, solid silica gel molding is the material is a piece of solid, through mixing machine mixing, cutting machine into the appropriate size and thickness of the product and mold, and then put into the mold, pressure molding machine under a certain temperature molding. Demoulding and plastic products are similar, but also need to finish the mold.

From the production of the difference:

Liquid silica gel has high lightness, no peculiar smell, and the product has a glue injection mouth.

Solid silica gel clarity is low, vulcanizing agent or other cover vulcanizing agent fragrance, the product has no glue injection mouth.