Along with the development of organic silicon industry, improve technical level and technical requirements of products, processing liquid silicone molding process has become the mainstream of the production of silicone products, if anyone want to liquid silicone products of high quality, choice of liquid silicone injection molding process is without any faults, so pay attention to the current liquid silicone processing technology development trend, when technology matures, Liquid silica gel production of raw materials is a certain limitation, high hardness of liquid silica gel technology mature?

Liquid silicone raw materials, after more than 50 degrees commonly products processing difficulty will increase, because the liquid silicone molding, unlike solid silicone molding, raw material for water paste, when higher hardness, mix and preparation will have trouble, with the increase of hardness, the tear resistance of materials is lower, the higher the hardness of products, the more prone to fracture and damage.

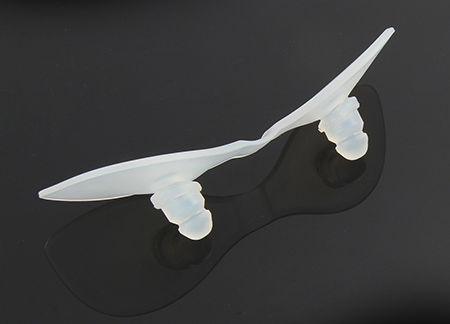

High rigid sealing liquid silica gel is a kind of products, many products used at present in our life, high hardness larger proportion of silica gel products, whether in performance or on the handle is good, but a lot of silicon factory don't want to use high hardness liquid silicone material, because of high hardness of the material in the mold in the feed speed is slow, The production process will seriously affect the efficiency and loss of the mold, and it is very easy to produce high quality products.

Current solid processing technology has been broke the hardness requirement for 90 degrees, with mature technology, the future is likely to exceed 100 degrees or higher hardness, and in the liquid silicone of high hardness silicone materials in the production process, the technology is not yet mature, both to ensure that the material liquidity and high toughness, and to ensure that the raw material in the absence of any additives, Vulcanization molding time and fluidity, so the material has been limited to low temperature, difficult to break through.

But in terms of the current market, IT is believed that in the near future, high hardness silica gel liquid raw materials will gradually break through this limitation.