The main technical

The liquid silicone product is a new type of silicone rubber which uses excessive metal complex (platinum, nickel, rhodium, etc.) as catalyst to bridge si-H and Si-CH=CH2 and get silicone rubber elastomer.

At the beginning of 1970s, liquid silicone rubber satisfying injection molding process began to be studied abroad. But due to all aspects of technology are not mature, can only be suitable for extrusion molding process. In the 1980s, the development of liquid silicone rubber was slow. There were several technical problems that were difficult to solve. First, the contradiction between good liquidity and high strength was guaranteed. Second, how to ensure that there is enough operation time not to cross link after no material mixing; Three is the limitation of mold design level.

The 1990s, is the era of great development of liquid silica gel, first of all, a large number of MQ silicone rubber to solve the contradiction of silicone rubber fluidity and strength; Secondly, the technology of cross-linking inhibitors has also been improved, from the simple use of alkynyl alcohol compounds to the use of alkynyl alcohol and siH-containing polysiloxane addition products, platinum microcapsule technology has also made great progress. Third, the cold flow module technology of mold design also clears the way for liquid silicone rubber in the process.

After the 1990s, the variety of silicone rubber began to diversify. At present, almost all kinds of high temperature silicone rubber, liquid silicone rubber, and its performance is better than room temperature vulcanized silicone rubber (HTV). This broadens the application space for liquid silicone rubber.

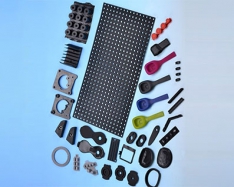

Organic silicon products industry chain upstream and methyl chloride as raw materials for the silicon powder was synthesized dimethyl dichlorosilane several industrial value of organic silicon monomer, such as the production of organic silicon monomer long process flow, technical difficulty is big, is a technology-intensive and capital-intensive industries, its production level and device size are important basis to measure a country's organic silicon technology. Silicone monomer through hydrolysis, cracking and other processes to make silicoxane as a representative of silicone material intermediates, intermediates further synthesis to obtain silicone oil, silicone rubber, silicone resin, silane coupling agent and other four categories of deep processing products. In the four categories of silicone deep processing products, silicone rubber production is large, in the composition of silicone products accounted for 60~70 percent.

From the downstream application of organic silicon processing products industry development trends, as the global coal and oil resources dwindling, the trend of organic silicon products replace traditional petrochemical industry is more and more obvious increase, its applications in addition to construction, electric power, machinery processing, textile, leather, daily necessities, personal care products, medicine and other traditional areas, In recent years, the application in solar energy, wind power, high-speed rail, automobile, electronic information technology, medical and health care, high-end manufacturing, energy conservation and environmental protection and other industries has also been expanding.